Visit at ABiTEP GmbH

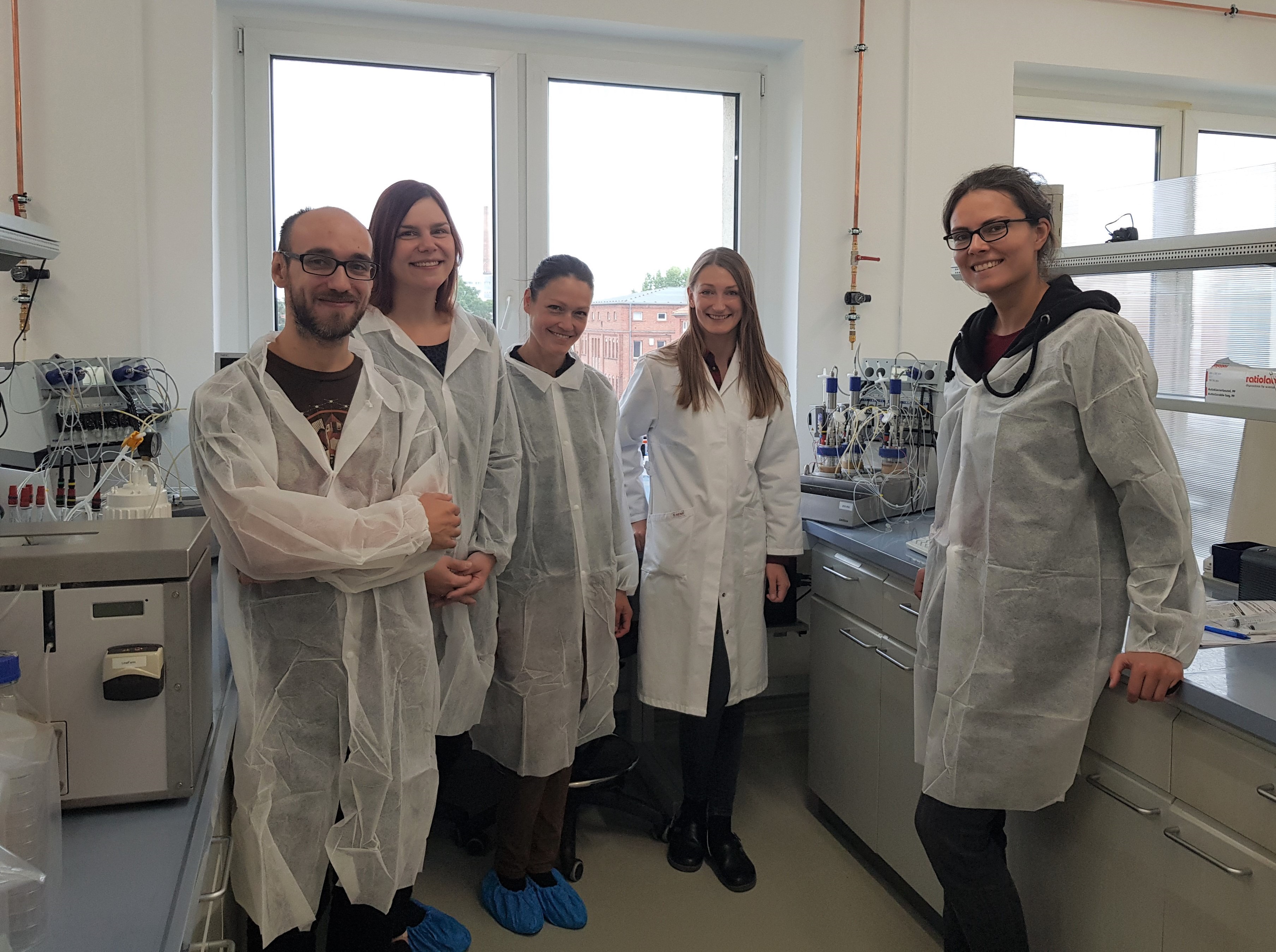

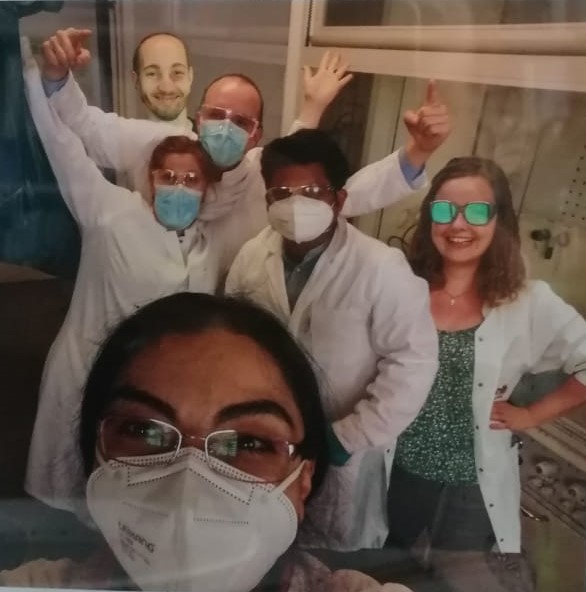

Yesterday, innoFSPEC members Anika Krause, Anne Hartwig and Marvin Münzberg as well as Anika Bockisch from Bio-PAT e.V. visited the ABiTEP GmbH to discuss possible joint projects in the future, starting with a feasibility study of using PDW to monitor production processes at ABiTEP. We're looking forward to our collaboration!